Magnetic Position Sensors

Dual-Die Programmable Linear Hall IC with Advanced Diagnostics for Safety-Critical Applications

A1346

These parts are in production but have been determined to be NOT FOR NEW DESIGN. The A1346 is a dual high-precision, programmable Hall-effect linear sensor IC with full die redundancy and advanced diagnostics for safety-critical applications. It features 16-segment linearization and proprietary SSENT/ASENT protocols for multi-device communication, ensuring high diagnostic coverage and availability.

Product Details

Product Details

Top Features

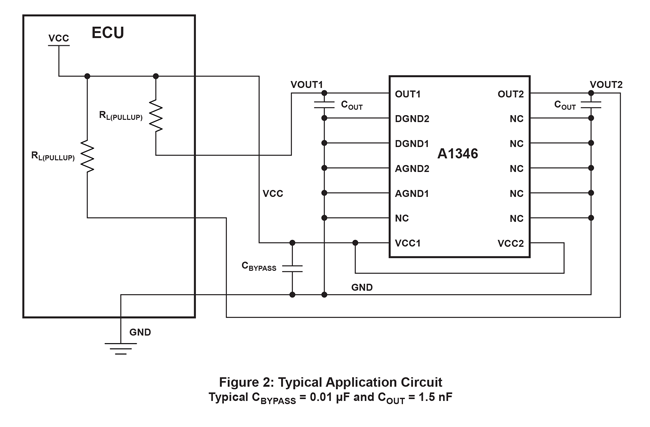

- Two electrically isolated die in one package for the most safety-critical applications

- In the event of a die failure, self-diagnostics allow the controller to discern which die to continue to trust

- For diagnostics that impact response, these diagnostics can be run on each die while the other is fully operational

- For all features below, these refer to each of the two die in the package

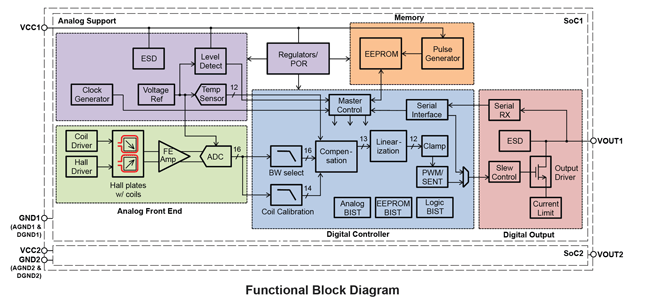

- High-speed analog, A-to-D converter (ADC), and digital architectures, enabling user-selectable bandwidth for speed-sensitive applications

- 4-phase chopper stabilization, which minimizes offset drift across temperature range

- 16-bit, high update rate ADC

- Exceptional stability throughout lifetime and across temperature changes

- Factory-configured using multisegment temperature compensation to give a flat baseline across operating temperature range

- Customer configurability for 1st and 2nd order sensitivity and 1st order offset compensation across temperature range

- Integrated feedback coil compensates for drift throughout product lifetime

- Wide operating flexibility to meet any application:

- Field range from ±40 to ±1800 gauss

- Rail to negative rail offset configurability

- High-precision, full output range high and low clamps

- Integrated linearization allows for flexible output waveform translation and compensation for nonlinear magnetic inputs

- Advanced diagnostic-focused features enabling easier systemlevel ASIL compliance

- Full data path validation through active front-end stimulation with internal magnetic coil; this method validates all relevant transistors for device operation

- Logic Built-In Self Test (LBIST) on-demand to validate the digital subsystem

- Large suite of configurable fault monitors provide system level fault detection, including:

- Overvoltage or undervoltage

- Overtemperature

- Magnetic Field Out of Range detection

- Broken wire detection

- Flexible output protocols with up to 12-bit resolution and configurable error notifications

- Digital open-drain output allows for flexible output voltage levels

- PWM (Pulse-Width-Modulated) output with diagnostic output mode to identify fault conditions

- SENT (Single Edge Nibble Transmission) compliant output with configurable reporting of error conditions and other diagnostic information

- Proprietary Fast SENT provides increased data rates to support high-bandwidth applications

- Device-shared SENT protocol as SSENT (Sequential SENT) and ASENT (Addressable SENT) allows user to connect up to 4 devices on the same output line for faster communication.

- Enhanced EMC tuning through programmable fall-time configurability

- Integrated EEPROM enables a high level of configurability and product traceability

- Customer-reserved area allows on-board storage of unique lot and date code information

- Robust EEPROM with Single Error Correction and Double Error Detection (SECDED), capability

- Integrated charge pump allows in-application programming without any requirement for high voltages to be supplied to the device during programming

- Allegro Sensor Bias LDO